TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Case study: How to Create a Reflow Profile for a 16-layer, 2mm Thickness PCB with a High Density SMT Connector?

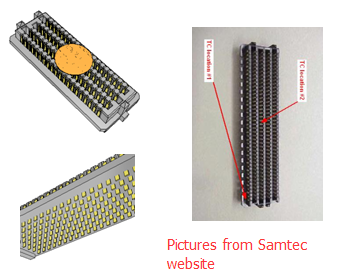

A high density SMT connector, such as the Samtec .050" SEARAY™ High Speed High Density Open Pin Field Array, has up to 500 I/O contact pins with a solder charge termination.

This type of connector looks like a standard BGA type of SMT device. A proper thermal profile for reflow must be evaluated by the process engineer prior to production.

- Thermocouple (TC) location To verify the correct reflow profile, 2~3 thermocouples should be placed beneath the connector: one (1) in the leading corner position, one (1) in the middle of the connector, and one (1) at the trailing corner (optional). These theremocouple placements ensure that all areas of the connector receive even heating sumultaneously.

-

Soak time and TAL consideration

To ensure proper temperature equalization of the whole area beneath the connector, it is recommended that the soak time is long enough as well as the time above liquidus be long enough for a total reflow. Of course, all data must meet with the solder paste manufacturer’s specifications. -

Preheat and cooling set point

A PCB’s physical properties are also another critical consideration for correct profile adjustment. In this case, the PCB has 16 layers and a 2mm thickness. This mean that this bare board has a high thermal resistance. So, the preheat set point can be adjusted higher than normal; however, the cooling point may lower than normal in order to meet TAL within the specifications.

Here are the testing results in this case study: (Note: this is for reference only):

- Reflow oven : Concept 7 zone

- TAL : 60 sec

- Peak temperature: 245°C

| Board property | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 |

|---|---|---|---|---|---|---|---|

| 1.6mm, Dual layer, bare PCB | 110 | 130 | 160 | 180 | 180 | 220 | 250 |

| 2.0mm, Dual layer, bare PCB | 110 | 135 | 165 | 185 | 185 | 220 | 250 |

| 2.0mm, 16 layer, bare PCB | 120 | 145 | 180 | 185 | 190 | 230 | 255 |

| 2.0mm, 16 layer, Samtec SEAM connector | 125 | 150 | 185 | 195 | 195 | 255 | 275 |

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English